Isigaba

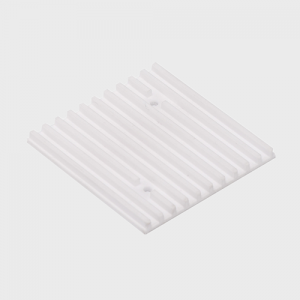

I-ceramic heat sink iyisisetshenziswa esihlakaza ukushisa ezingxenyeni ze-elekthronikhi ezithambekele ekushiseni zento kagesi.Njengamanje, ishidi le-alumina ceramic elivame ukusetshenziswa, ishidi le-aluminium nitride ceramic, ishidi le-silicon carbide ceramic.

Ishidi le-alumina ceramic: Inokusebenza kahle kwe-thermal, i-thermal conductivity: 24W / MK, izinga lokushisa eliphezulu / ukumelana nokucindezela okukhulu, ukushisa ngokulinganayo, ukuchithwa kokushisa okusheshayo.Ngaphezu kwalokho, inesakhiwo esilula futhi esihlangene, usayizi omncane, indawo ebushelelezi, amandla aphezulu futhi akulula ukuphuka, ukumelana nokugqwala kwe-asidi ne-alkali, okuhlala isikhathi eside.

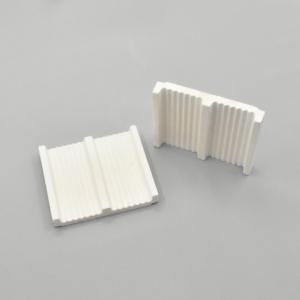

Ishidi le-aluminium nitride ceramic: Umbala umpunga omhlophe, indawo ebushelelezi, ungenziwa ngokwezifiso ube yinoma yikuphi ukuma noma usayizi, kulula ukuwusebenzisa nokufaka.Le radiator ye-ceramic ine-conductivity ephezulu kakhulu ye-thermal, i-thermal conductivity yizikhathi ezingu-7-10 zeshidi le-alumina ceramic, ingafinyelela ku-180W ukuphakama, ukusebenza kwayo kokufakwa kukagesi kuzinzile kakhulu, ukulahlekelwa kwe-dielectric kanye nokulahlekelwa okuphakathi kuphansi, kungakwazi ukumelana no-1800 degrees Celsius futhi akuthinti ukusebenza komkhiqizo.Ngokuthuthuka okusheshayo kwemishini ye-elekthronikhi, isidingo semikhiqizo ye-elekthronikhi noma eyisizayo siyakhula, futhi izinga lokusetshenziswa kwalo mkhiqizo njengeshidi le-aluminium nitride ceramic conductivity elishisayo njenge-matrix noma impahla yokupakisha liya ngokuya likhula emakethe. .

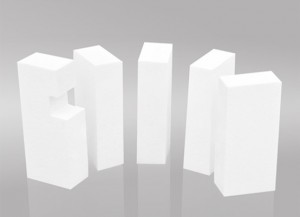

Ishidi le-silicon carbide ceramic: Kuyizinto eziluhlaza zokuvikela imvelo, kungokwesakhiwo se-microporous, endaweni efanayo yeyunithi ingaba ngaphezu kwe-30% ye-porosity, yandisa kakhulu indawo yokushisa ukushisa kanye nokuxhumana komoya, ukuthuthukisa umphumela wokushisa ukushisa.Ngesikhathi esifanayo, amandla ayo okushisa amancane, isitoreji sayo sokushisa sincane, ukushisa kungadluliselwa emhlabeni wangaphandle ngokushesha, izici eziyinhloko ze-ceramic heat sink: ukuvikelwa kwemvelo, ukufakwa kwe-insulation kanye nokumelana nokucindezela okukhulu, ukuchithwa kokushisa okuphumelelayo. , ukugwema ukuzalaniswa kwezinkinga ze-EMI.Ingakwazi ukuxazulula ngokuphumelelayo izinkinga zokuqhuba ukushisa kanye nokuchithwa kokushisa embonini ye-electronics kanye nemishini yasendlini.Ngesikhathi esifanayo, ifaneleka ngokukhethekile ukusetshenziswa kwamandla wattage amancane naphakathi.Isikhala sokuklama sinaka imikhiqizo ekhanyayo, emincane, emifushane nemincane, enganikeza ukwesekwa kwezobuchwepheshe kanye nesicelo sokusungula nokuthuthukiswa kwemikhiqizo ye-elekthronikhi.

Izinzuzo

I-1.I-Ceramic heat sink ingakhipha ukushisa ngokuqondile, futhi isivinini sishesha kakhulu, sinciphisa ithonya le-insulation layer ekusebenzeni kahle kokushisa;

I-2.I-Ceramic heat sink iyisakhiwo se-polycrystalline, lesi sakhiwo singaqinisa ukuchithwa kokushisa, ngaphesheya kwemakethe izinto eziningi zokushisa ezishisayo;

I-3.I-Ceramic heat sink ingaba i-multi-directional heat dissipation, isheshisa ukuchithwa kokushisa;

I-4.I-Ceramic heat sink's insulation, i-thermal conductivity ephezulu, ukumelana nokushisa okuphezulu, ukumelana nokushisa okuphezulu, ukumelana nokugqoka, amandla aphezulu, ukumelana ne-oxidation, ukumelana ne-asidi ne-alkali, impilo ende yesevisi, i-coefficient ephansi yokwandisa okushisayo ingaqinisekisa ukuzinza kwe-ceramic heat sink in. izinga lokushisa eliphezulu neliphansi noma enye indawo enokhahlo;

I-5.I-Ceramic heat sink ingakwazi ngokuphumelelayo ukulwa nokuphazamiseka (EMI), i-anti-static;

I-6.I-Ceramic heat sink isebenzisa izinto zemvelo eziphilayo, ukuhlangabezana nezidingo zokuvikelwa kwemvelo;

I-7.I-Ceramic heat sink's volume encane, isisindo esincane, amandla aphezulu, ingasindisa indawo, yonga izinto zokwakha, yonga impahla, evumelana kakhulu nesakhiwo esinengqondo sokuklama komkhiqizo;

I-8.I-Ceramic heat sink ingakwazi ukumelana namanje, i-voltage ephezulu, ingavimbela ukuwohloka kokuvuza, akukho msindo, ngeke ikhiqize ukuhlanganisa amandla e-parasitic ne-MOS namanye amashubhu wamandla, ngakho-ke yenza inqubo yokuhlunga ibe lula, idinga ibanga le-creepage lifushane kune- izidingo zomzimba wensimbi, zingaqhubeka zisindise isikhala sebhodi, zivumelane kakhulu nomklamo wonjiniyela kanye nezitifiketi zikagesi.

Isingeniso Sohlelo

Isinki sokushisa kwe-Ceramic sisetshenziswa kakhulu ezingxenyeni zomkhiqizo ezidinga ukufakwa kokushisa kokushisa, okufana nemishini enamandla amakhulu, ishubhu le-IC MOS, uhlobo lwe-IGBT patch ye-heat conduction insulation, ukunikezwa kwamandla aphezulu, ukuxhumana, okokusebenza kwemishini.Ngaphezu kwalokho, i-radiator ye-ceramic izophinde isetshenziswe ekukhanyeni kwe-LED, i-welder high frequency, i-amplifier yamandla / umsindo, i-transistor yamandla, i-module yamandla, i-chip IC, i-inverter, inethiwekhi / i-broadband, ukunikezwa kwamandla ka-UPS nokunye.

Imboni Yezogesi

Imboni Yokukhanyisa

Imboni yezindwangu

Imboni ye-Petrochemical

-

I-Self-lubricating Ceramic Shaft kanye ne-Shaft seal

-

Ceramic Water Valve Plate Disc

-

I-Sintering Fixture

-

I-Alumina Hollow Bulb Brick / Alumina Bubble Brick

-

I-granulation powder

-

I-alloy cutoff eshisayo