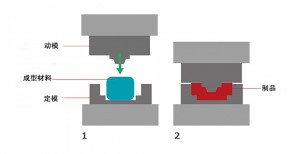

Dry pressing molding method

Alumina ceramic dry pressing molding technology is limited to pure shape and wall thickness more than 1mm, length to diameter ratio is not more than 4∶1 products. Forming methods are uniaxial or biaxial. The press has hydraulic, mechanical two kinds, can be semi-automatic or automatic molding. The maximum pressure of the press is 200Mpa, and the output can reach 15 ~ 50 pieces per minute.

Due to the uniform stroke pressure of hydraulic press, the height of pressing parts is different when the powder filling is different. However, the pressure applied by mechanical press varies with the amount of powder filling, which will easily lead to the difference in size shrinkage after sintering and affect the quality of products. Therefore, the uniform distribution of powder particles in dry pressing process is very important for mold filling. Whether the filling quantity is accurate or not has great influence on the dimensional precision control of manufactured alumina ceramic parts. The maximum free flow effect can be obtained when the powder particles are larger than 60μm and between 60 ~ 200 mesh, and the best pressure forming effect can be obtained.

Grouting molding method

Grouting molding is the earliest molding method used in alumina ceramics. Due to the use of gypsum mold, low cost and easy to form large size, complex shape parts, the key of grouting molding is the preparation of alumina slurry. Usually with water as the flux medium, and then add the glue dissolving agent and binder, fully after grinding exhaust, and then poured into the plaster mold. Due to the adsorption of water by the capillary of the gypsum mold, the slurry is solidified in the mold. Hollow grouting, in the mold wall adsorption slurry thickness up to the required, but also need to pour out the excess slurry. In order to reduce the shrinkage of the body, high concentration slurry should be used as far as possible.

Organic additives should be added to the alumina ceramic slurry to form a double electric layer on the surface of slurry particles so that the slurry can be suspended stably without precipitation. In addition, it is necessary to add vinyl alcohol, methyl cellulose, alginate amine and other binder and polypropylene amine, Arabic gum and other dispersants, the purpose is to make the slurry suitable for grouting molding operation.

Sintering technology

The technical method of densifying granular ceramic body and forming solid material is called sintering. Sintering is the method of removing the void between the particles in the body of the billet, removing a small amount of gas and impurities from the organic matter, so that the particles grow together and form new substances.

The heating device used for firing is generally an electric furnace. In addition to normal pressure sintering, that is, without pressure sintering, hot pressing sintering and hot isostatic pressing sintering. Continuous hot pressing can increase production, but the cost of equipment and mold is too high, in addition to the length of the product is limited. Hot isostatic pressure sintering adopts high temperature and high pressure gas as pressure transfer medium, which has the advantage of uniform heating in all directions, and is suitable for sintering of complex products. Because of the uniform structure, the properties of the material are increased by 30 ~ 50% compared with cold pressing sintering. 10 ~ 15% higher than ordinary hot pressing sintering.

Post time: May-12-2022